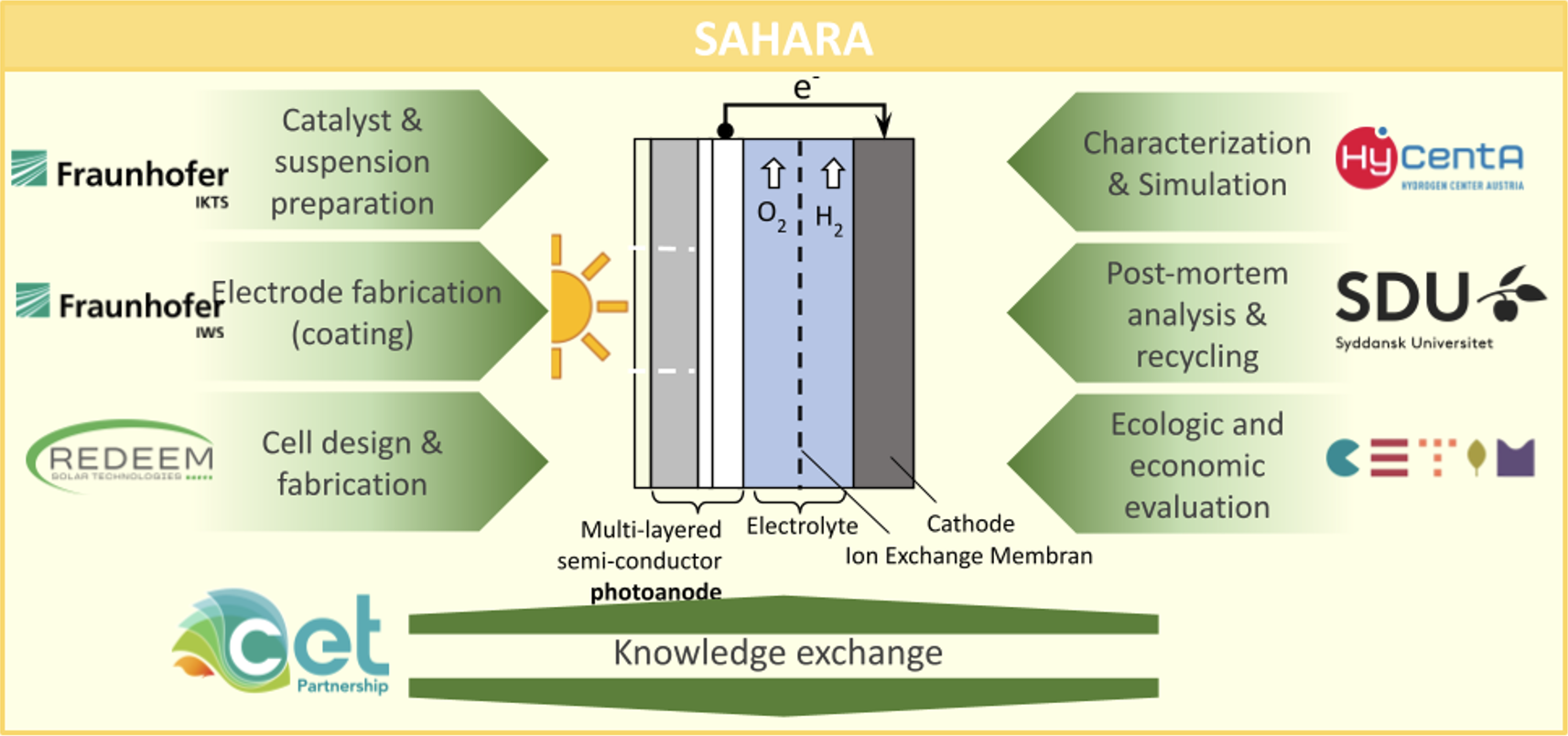

Our mission

At SAHARA, we are pushing the boundaries of photoelectrochemical (PEC) technology to unlock a cleaner, more sustainable future for green hydrogen production. Our goal is to elevate PEC technology to new levels of efficiency, scalability, and economic viability—transforming solar energy directly into high-purity hydrogen through an innovative floating reactor cell.

Key objectives

SAHARA is designed to bridge the gap between laboratory research and real-world application by focusing on:

Scalability

Expanding the active PEC cell area for industrial-scale hydrogen production.

Sustainability

Reducing the carbon footprint by incorporating recycled materials and improving catalyst recovery.

High-Purity

Hydrogen

Targeting 99.9% purity at 5-bar operating pressure to meet industry standards

Cost

reduction

Lowering PEC component costs by 20% and aiming for an H₂ production cost of <4 €/kg.

Efficiency

Optimizing solar-to-hydrogen (STH) conversion with a goal of >10% efficiency.

Innovative

Zero-Gap Design

Enhancing reaction kinetics and charge transfer for higher stability and performance.

Expected impact

400 cm²

Active PEC cell area

< 4€/kg

PEC component costs and H₂ production

>10%

STH efficiency

>85%

H₂ evolution efficiency

<60%

CO₂ emissions

Overcoming Challenges

While electrolysis remains the dominant method for hydrogen production, PEC water splitting presents a game-changing alternative—a standalone, decentralized system with potentially higher solar-to-hydrogen efficiency than PV + electrolysis. However, key challenges must be addressed:

Durability & Stability

Photoelectrodes and catalysts degrade over time, affecting performance.

SAHARA tackles this with advanced material development to enhance longevity.

Technology Readiness

We aim to progress PEC from TRL 3-4 to TRL 6, ensuring a more mature and deployable technology.

TRL 3-4

TRL 6

Cost & Sustainability

Through catalyst recycling (>90% recovery) and a focus on sustainable materials, we lower costs and emissions by 60% compared to steam reforming.

60%